The extensive spectrum of measured values can be determined with highest accuracy up to 0.03 %. The measuring accuracy is traceable to international standards.

The measurement, which takes only a few seconds, is easy to start and ensures a high test sample throughput. The exact autofocus scan also makes the measurement user-independent and objective.

The measurements can be efficiently designed through individual processes and the user-specific selection of the measurement parameters.

Manual focusing

Focal length measurements of up to ±250 mm

Measurement of back focal length (BFL) as well as flange focal length (FFL) and curvature radius from ±5 mm up to ±250 mm

High precision autofocus

Measurement of back focal length (BFL) as well as flange focal length (FFL) and curvature radius from ±5 mm up to ±490 mm

Automated focusing

Focal length measurement up to +500 mm

Measurement of back focal length (BFL) as well as flange focal length (FFL) and curvature radius from +5 mm up to +490 mm

Focal length measurement from 0.3 mm to 12 mm

Flange and back focal length measurement between -5 mm and +40 mm

Precise positing of the measuring head allows high measurement accuracy for flange and back focal length of ±4 µm

Quick testing of single lenses in just 12 seconds

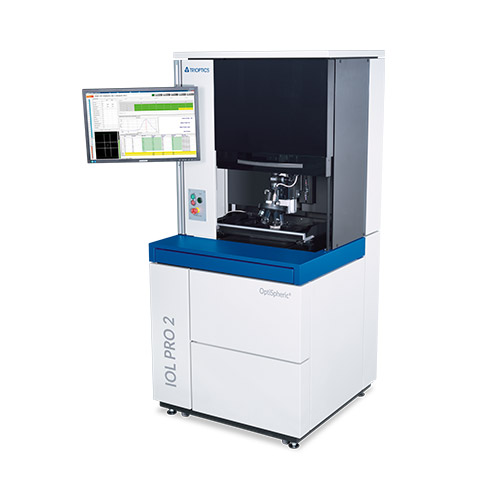

ISO-compliant measurement of hydrophobic and hydrophilic lenses in air or in a heatable in situ eye model according to ISO 11979

Power measurement with an accuracy of 0.3 % for all types of intraocular lenses

High throughput with up to 100 lenses per tray

ISO-compliant measurement of hydrophobic and hydrophilic lenses in air or in a heatable in situ eye model according to ISO 11979

Power measurement with an accuracy of 0.3 % for all types of intraocular lenses

We will show you how OptiSpheric® HR allows for high-precision inspection of short focal length lenses.

Register here & watch the videoComprehensive, reliable functionalities that can be used both in production and in research and development

Optimization of the test sequence through customer-specific programming of measurement and analysis sequences using script tooling – ideal for R&D laboratories

Simple operation through predefined measurement processes for various IOL types

Easy system setup with just a few clicks to start the fully automated alignment and measurement of batches with up to 100 IOLs

Flexible, modular menu navigation that can be set up for different users (R&D, production, administrator)

| Parameter |

OptiSpheric® Manual focusing, automated measurement |

OptiSpheric® Auto Focus 500 automated measurement |

OptiSpheric® Auto Focus 1000 automated measurement |

OptiSpheric® Auto Focus 1500 automated measurement |

OptiSpheric® Auto Focus 2000 automated measurement |

| Lens diameter | 3 mm ... 35 mm optional: 5 mm ... 75 mm |

3 mm ... 35 mm optional: 5 mm ... 75 mm |

5 mm ... 75 mm optional: 3 mm ... 35 mm |

5 mm ... 75 mm optional: 3 mm ... 35 mm |

5 mm ... 75 mm optional: 3 mm ... 35 mm |

| Clear aperture | 28 mm | 28 mm | 48 mm | 48 mm | 48 mm |

| EFL (Effective Focal Length) | +5 mm … +250 mm -5 mm … -250 mm |

+5 mm … +450 mm -5 mm … -450 mm |

+5 mm … +1,000 mm -5 mm … -1,000 mm |

+5 mm … +1,500 mm -5 mm … -1,200 mm |

+5 mm … +2,000 mm -5 mm … -1,500 mm |

| Measurement range BFL and radius |

±5 mm … ±250 mm | ±5 mm … ±490 mm | ±5 mm … ±490 mm | ±5 mm … ±750 mm | ±5 mm … ±1,000 mm |

| MTF | absolute MTF-Test: 5 mm … 50 mm EFL |

absolute MTF-Test: 5 mm … 50 mm EFL |

absolute MTF-Test: 5 mm … 50 mm EFL |

absolute MTF-Test: 5 mm … 50 mm EFL |

absolute MTF-Test: 5 mm … 50 mm EFL |

| Parameter | OptiSpheric® AF 500 INV |

| Lens diameter 1) | 5 mm … 75 mm |

|

EFL (Effective Focal Length), relative MTF: range |

+5 mm … +500 mm 3) |

| EFL, relative MTF: measurement accuracy 2) |

5 mm … 25 mm: 0.1 % … 0.3 % 25 mm ... 500 mm: 0.03 % … 0.1 % 500 mm … 1000 mm: 0.05 % … 0.3 % |

| EFL, relative MTF: measurement time |

First measurement: 5 s … 8 s consecutive measurements : 3 s … 5 s |

| BFL, FFL, radius: range | +5 mm … +490 mm |

| BFL, FFL, radius: repeatability 2) |

0.02 % ... 0.2 % |

| BFL, FFL, radius: accuracy 2) | 0.03 % ... 0.3 % |

| MTF up to 150 lp/mm: range | 5 mm … 75 mm EFL (Effective Focal Length) |

| MTF up to 150 lp/mm: test mode |

Axial MTF measurement automatic auto focus |

| MTF up to 150 lp/mm: spatial frequency |

0 lp/mm … 500 lp/mm |

| MTF up to 150 lp/mm: repeatability 2) |

1% |

| MTF up to 150 lp/mm: accuracy 2) |

2% |

| Wavelength | 546 nm 4) |

| Dimensions (h x w x d) | 1,950 mm x 1,205 mm x 700 mm |

| Weight | 280 kg |

| Type | Stand alone device |

1) Sample holder for other lens diameters upon request

2) Depending on NA of sample; higher NA reduces accuracy; sample NA should be smaller than NA of the measurement head

3) Negative measurement range upon request

4) Other wavelengths (e.g. 480 nm, 658 nm) upon request

| Parameter | OptiSpheric® HR |

| EFL measurement range | 0.3 mm to 12 mm |

| EFL measurement accuracy 1) |

+0.5 mm … +3 mm: ±5 μm +3 mm … +12 mm: 0.2 % |

| EFL repeatability 1) |

+0.5 mm … +3 mm: < ±5 μm +3 mm … +12 mm: < 0.2 % |

| FFL measurement range | -5 mm to +40 mm |

| FFL measurement accuracy | ±4 μm (2 sigma) |

| FFL repeatability | 2 μm |

| BFL measurement range | -5 mm to +40 mm |

| BFL measurement accuracy | ±4 μm (2 sigma) |

| BFL repeatability | 2 μm |

| MTF measurement range | up to 150 lp/mm |

| MTF measurement accuracy 1) | ±2 % MTF |

| MTF repeatability 1) | ±1 % MTF |

| Dimensions (W x H x D) | approx. 500 mm x 1100 mm x 570 mm |

| Weight | 40 kg |

| Type | Tabletop device |

1) For NA < 0.28; Depending on NA of sample: higher NA reduces accuracy

| Parameter | OptiSpheric® IOL R&D | OptiSpheric® IOL PRO 2 |

| Power range |

|

|

| Power accuracy | 0.3 % | 0.3 % |

| MTF range |

|

|

| MTF accuracy | ±2 % (0 ... 300 lp/mm) | ±2 % (0 ... 300 lp/mm) |

| Apertures diameter | 1 mm ... 6 mm with steps of 0.5 mm | 1 mm ... 6 mm with steps of 0.5 mm |

| Radius and BFL accuracy | 20 µm | 10 µm |

| Max. batch size | 1 | 100 |

| Sample positioning | Manual | Automatic |

| Dimensions (h x w x d) | 1,120 mm x 560 mm x 580 mm | 1,850 mm x 860 mm x 860 mm |

| Weight | 45 kg | 300 kg |

| Type | Table top device | Stand alone |

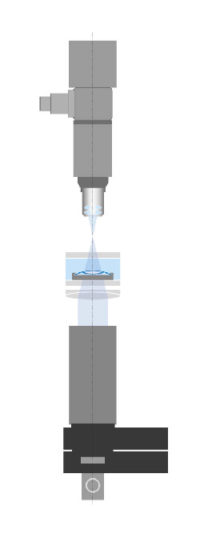

The OptiSpheric® IOL bench is using the imaging of an object through the lens under test. The resulting image is analyzed in order to evaluate the parameters of the lens (Power, Imaging quality through MTF calculation, energy distribution, Strehl ratio, and more…). Using this imaging technique is similar to realistic conditions and allows testing any type of IOLs designs.

Different types of target are projected to infinity through a collimator. The lens under test gives therefore an image of the target in its focal plane. A measuring CCD microscope is used for analyzing the image by the help of an autofocus mechanism. The instrument also includes different aperture sizes and different imaging objectives chosen automatically by the system according to the power of the lens under test. The wavelength used for the measurement is 546 nm as requested in the ISO 11979 standard.

Power, add power and cylinder are measured from the magnification of a double slit test target. The powers are determined in each focal planes of the IOLs, two different focal planes in case of a bifocal lens, two different crossed focal planes in case of a toric lens, four different focal planes in the case of a bifocal toric IOL, etc. The add power is calculated by subtraction of the near and far powers and the cylinder is calculated by subtraction of the crossed directions powers of a toric lens.

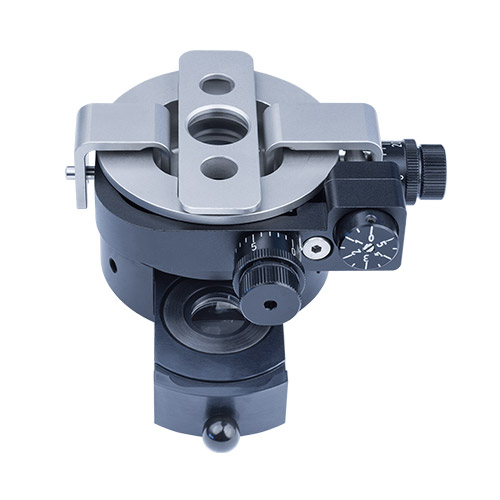

Setup for in-situ measurement

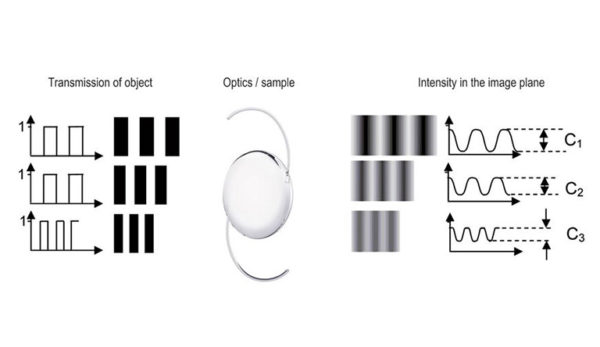

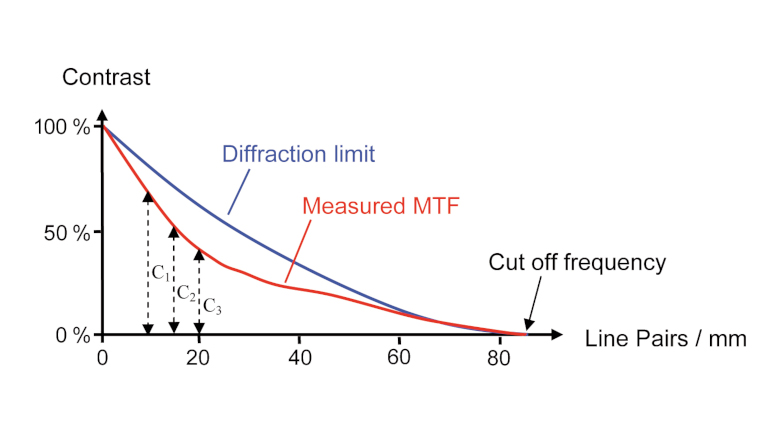

The measurement of the imaging quality is done through the evaluation of the Modulation Transfer Function (MTF). This objective and accurate method gives a full frequency resolved measurement of the optical quality.

The OptiSpheric® IOL measures the MTF on axis. It uses a single illuminated slit as object which is imaged on the focal plane of the sample. Due to diffraction and aberrations, there will not be a perfect slit image in this plane but a broadened slit, the so called Line Spread Function (LSF). The Fourier analysis of the LSF, giving the contribution of each spatial frequency, corresponds to the MTF of the sample. Alternatively to a slit it is also possible to use a cross (i.e. two perpendicular slits) giving the MTF in two image directions simultaneously or a pinhole giving as image a Point Spread Function (PSF) containing the complete MTF information in all directions.

The image of a narrow slit is called “Line Spread Function”

A perfect grid pattern is imaged through the sample into the image plane

MTF