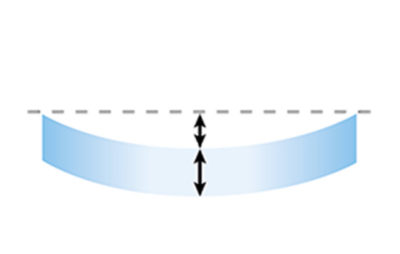

The used, established short coherence interferometry provides non-contact measurement results with an accuracy of up to ±0.5 µm. Vibration damping ensures reliable and environmentally independent measurement results.

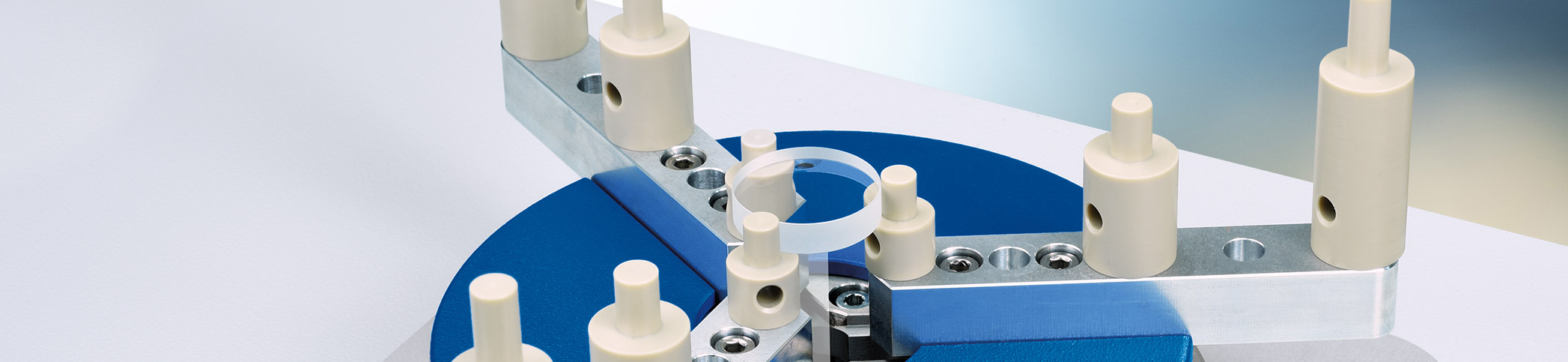

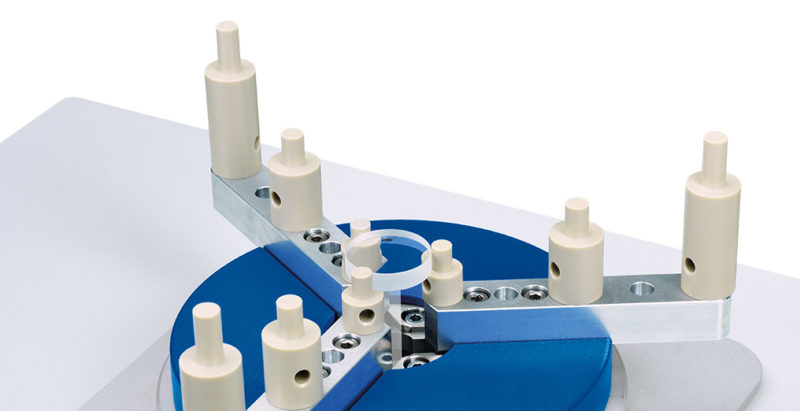

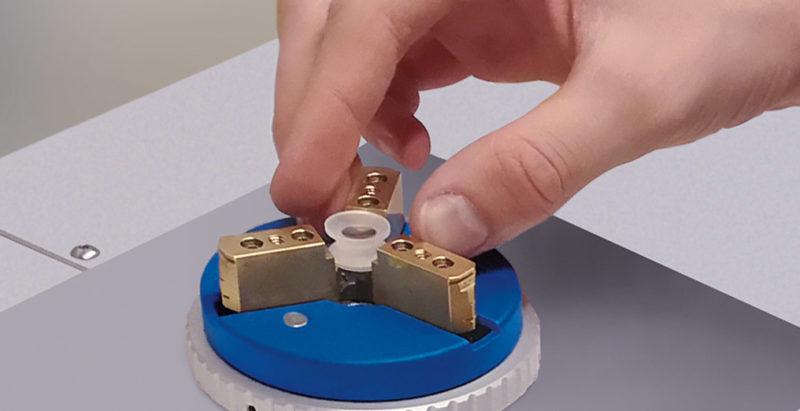

Due to the mechanical chucks, measurements without adjustment of the sample are possible. The data input and output is fast and comfortable via the network connection or a simple design editor.

With its integrated touch screen, the OptiSurf® LTM is particularly compact, robust and easy to use. Customer-specific adaptations such as barcode scanners, printers and other aids are of course possible.

We will show you how OptiSurf® LTM enables efficient target value monitoring in lens production.

Register here & watch the videoThanks to the easy-to-follow structure of the user interface, the measurement process is goal-oriented and the results are shown in a way that is easy to understand

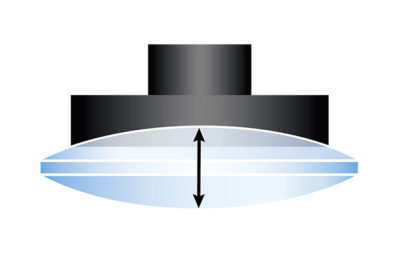

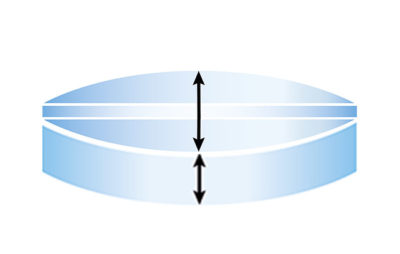

Automatic surface identification for fast and precise measurements

Direct quality analysis by means of pass/fail display as well as statistical analysis of measurement results

Direct embedding of the system in your processes, ensuring fast and error-proof data processing: The lens design can be entered directly from Zemax or via the OptiCentric® interface or via the practical Design Editor

| Parameter | OptiSurf® LTM |

| Max. diameter of the lens | 100 mm |

| Glass thickness | 0.05 mm … 50 mm, can be expanded to 150 mm |

|

Accuracy of center thickness measurement (geometric thickness) |

± 0.5 µm |

| Dimensions (h x w x d) |

390 mm x 504 mm x 504 mm |

| Weight | 30kg |

| Type | table top device |

This article inspired you? Are you looking for further knowledge transfer?

Then you might also be interested in the following topics …