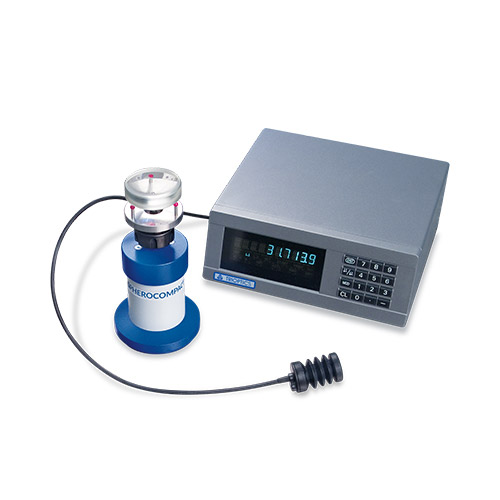

(SpheroCompact)

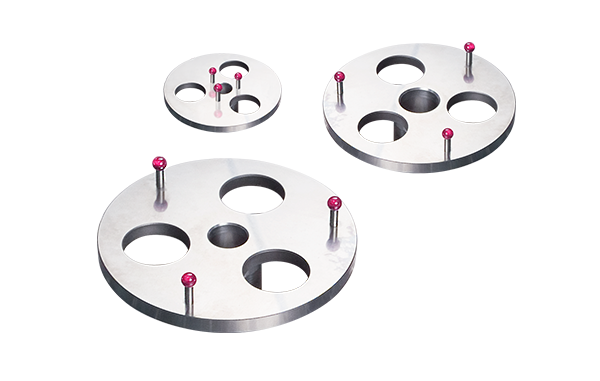

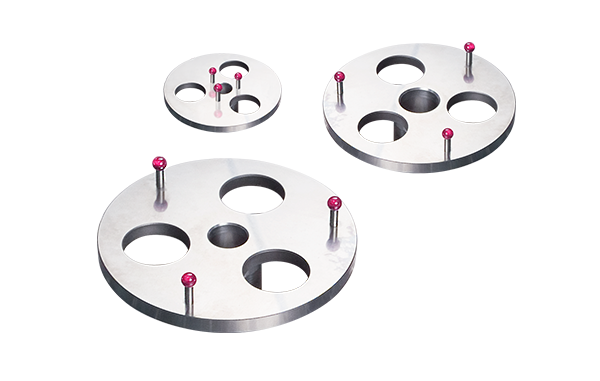

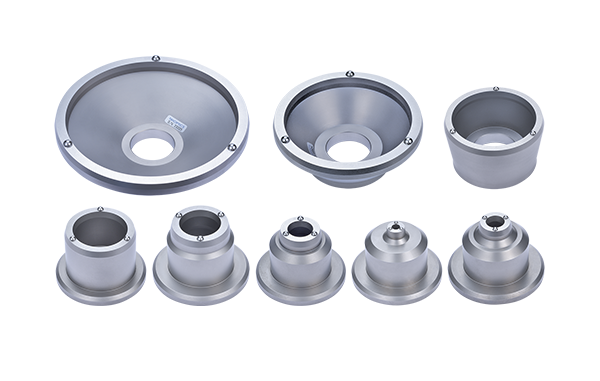

- Standard set (diameter):

12.5 mm, 25 mm, 50 mm, 75 mm, 100 mm, 125 mm -

Special sizes (diameter):

6 mm, 20 mm, 30 mm 38 mm, 40 mm, 150 mm, 225 mm - According to customer requirements

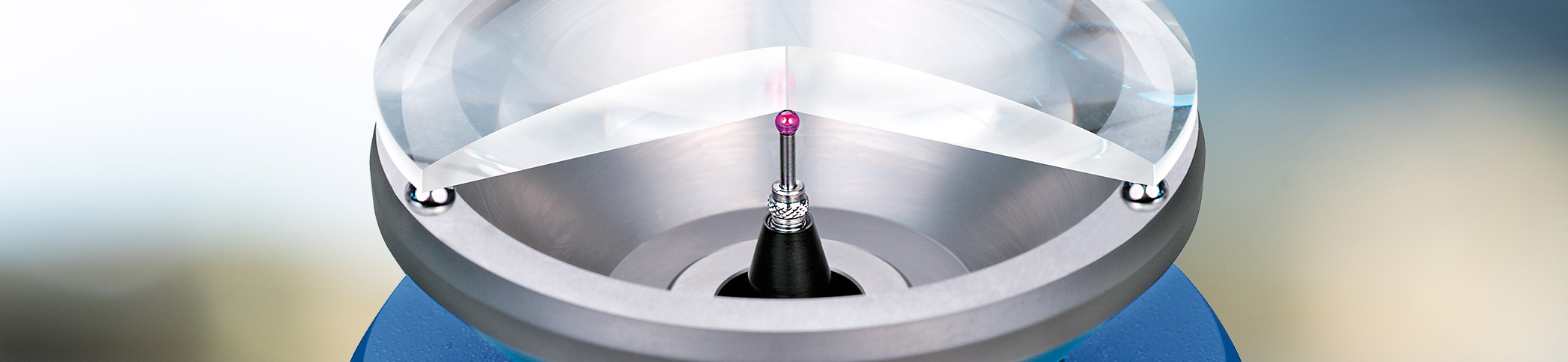

The high-precision ruby gauge head of the central encoder enables radius measurements with a measurement accuracy of up to ±0.005 %.

The certified measuring rings and precision optical flats allow traceability of the measuring accuracy to international standards. This sophisticated technology is therefore regarded as the gold standard for laboratories and manufacturing.

The selection of the model and associated selection of measuring rings with various diameters can be adapted to individual requirements. The versatile systems thus cover a very large measurement range.

Multi-purpose use, particularly for highly curved convex and concave surfaces because small radii of up to +2.5 mm and -4 mm especially can be measured

Its compact design allows SpheroCompact to be used flexibly

Spherometer optimized with regard to price and performance for use in manufacturing

Radius measurement of convex and concave surfaces up to +3 mm and -6 mm

Excellent precision for the measurement of highly curved surfaces with a large lens diameter by means of an increased travel of 60 mm

Extreme resistance to mechanical deformation thanks to the use of tungsten carbide balls in the ring

Radius measurement of convex and concave surfaces up to +3 mm and -6 mm

Excellent precision for the measurement of highly curved surfaces with a large lens diameter by means of an increased travel of 60 mm

Extreme resistance to mechanical deformation thanks to the use of tungsten carbide balls in the ring

The user-oriented software SpheroPRO was designed to fully meet the requirements in real-life applications. The intuitive user menu permits the easy, quick and error-free determination of the radius of curvature of lenses via pre-configured measurement programs. The current test step can be controlled directly by a schematic representation of the measured radius of curvature (concave or convex). Quality control is performed by means of a continuous statistical analysis of values.

| Parameter | SpheroCompact | SuperSpherotronic | UltraSpherotronic |

|---|---|---|---|

| Radius (convex) | +2,5 mm … ∞ | +2 mm … ∞ 1) | +2 mm … ∞ 1) |

| Radius (concave) | -4 mm … ∞ | -4 mm … ∞ | -4 mm … ∞ |

| Travel of linear encoder | ±12,5 mm | ±30 mm | ±30 mm |

| Diameter of sample | 6 mm … 500 mm | 6 mm … 500 mm | 6 mm … 500 mm |

| Resolution of the linear encoder | 0.1 µm | 0.1 µm | 0.02 µm |

| Absolute accuracy of the linear encoder | ±0.5 µm | ±0.5 µm | ±0.1 µm |

| Measurement accuracy 2) | Up to ±0.05 % | Up to ±0.01 % | Up to ±0.005 % |

| Height | 140 mm | 289 mm | 289 mm |

| Diameter | 90 mm | 185 mm | 185 mm |

| Weight | 1.5 kg | 6.5 kg | 6.5 kg |

| Type | table top device | table top device | table top device |

1) Measurement of radii < +4 mm requires the replacement of the ruby ball and the use of the precision ring 3.5 mm.

2) The maximum achievable measuring accuracy depends on the radius of the lens to be measured and the ring used. For detailed information on special measuring tasks, please contact your sales partner.

(SpheroCompact)

(SuperSpherotronic HR/UltraSpherotronic)

Mechanical pressure pad